|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Mining |

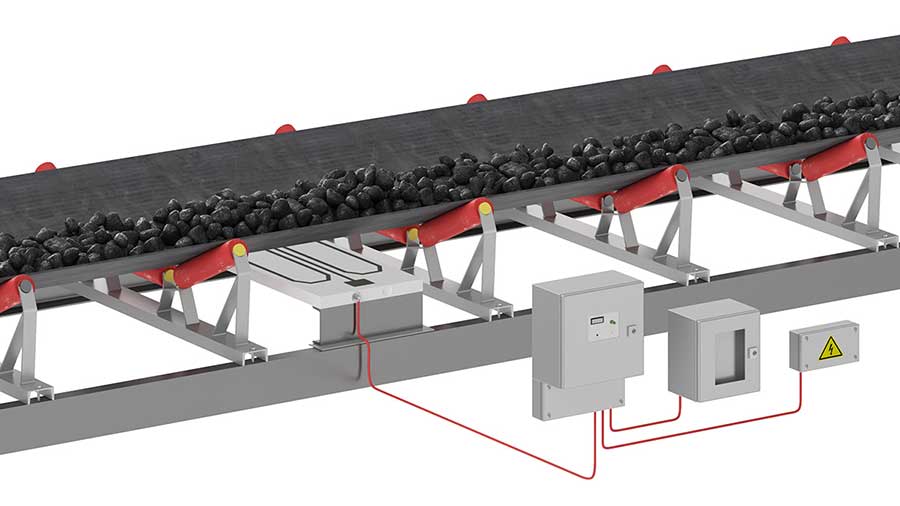

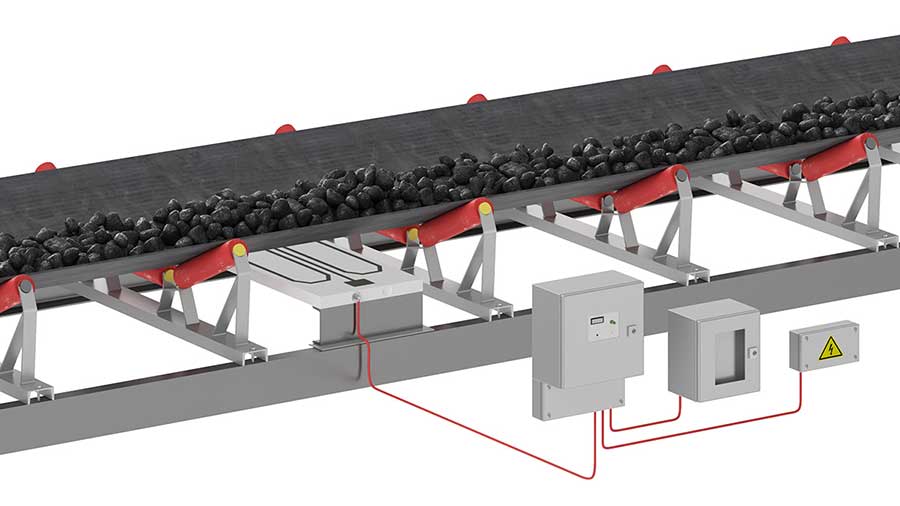

The Metal Detectors are designed to provide protection and monitoring against harmful pieces of metal in the material being conveyed. They prevent damage, avoids downtimes and produces significant savings on repair costs. The Metal Detectors are designed to provide protection and monitoring against harmful pieces of metal in the material being conveyed. They prevent damage, avoids downtimes and produces significant savings on repair costs.

Metal Detectors are well suited for quarries, lime works, clinker works, sand pits, cement factories, slag processing, building material recycling, brickworks and coal-burning power stations. |

| |

|

METAL SHARK® GF

For gravity-feed applications, round aperture, stainless-steel version, highest sensitivity.

- Product-effect teaching: yes

- Best sensitivity: Fe Ø 0.5 mm

- Pipe Ø 100 - 600 mm

|

|

METAL SHARK® TU

Divideable Tunnel-detector, for installation in conveyor-belts. Automatic adjustment of sensor, stainless-steel housing.

- Product-effect teaching: yes

- Sensing heights: 200 – 800 mm

- Best sensitivity: Fe Ø 1.2 mm

- Sensing widths: 200-2,000 mm

|

|

METAL SHARK® BIG

Very large and sturdy metal detector.

- Product-effect teaching: yes

- Best sensitivity: steel-nut M6

- Aperture width up to 800 – 4,500 mm

- Aperture height up to 1,400 mm

|

|

QLC / QLCTA

Made for high metal sensitivity for aggregate and mining.

- Sensing width: 200-2000mm makes it well suited for stone, coal and concrete.

- Belt speed: 0.3 – 6.0 m/s allows it to accommodate most production systems in the aggregate and mining industry.

- IP55 protection keeps the QLC protected from dust and solid objects common in harsh production environments.

|

|

SQ / SQTA

- Belt width: 500-1200mm

- Iron oxide and ore are ignored

- Detects both ferrous and non-ferrous metals

- Can be used in the proximity of frequency converters

- Probe and amplifier is immune to vibration and resistant to weather, dirt and impact from stones.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The Metal Detectors are designed to provide protection and monitoring against harmful pieces of metal in the material being conveyed. They prevent damage, avoids downtimes and produces significant savings on repair costs.

The Metal Detectors are designed to provide protection and monitoring against harmful pieces of metal in the material being conveyed. They prevent damage, avoids downtimes and produces significant savings on repair costs.