| PIP |

| Textile | |

|

|

|

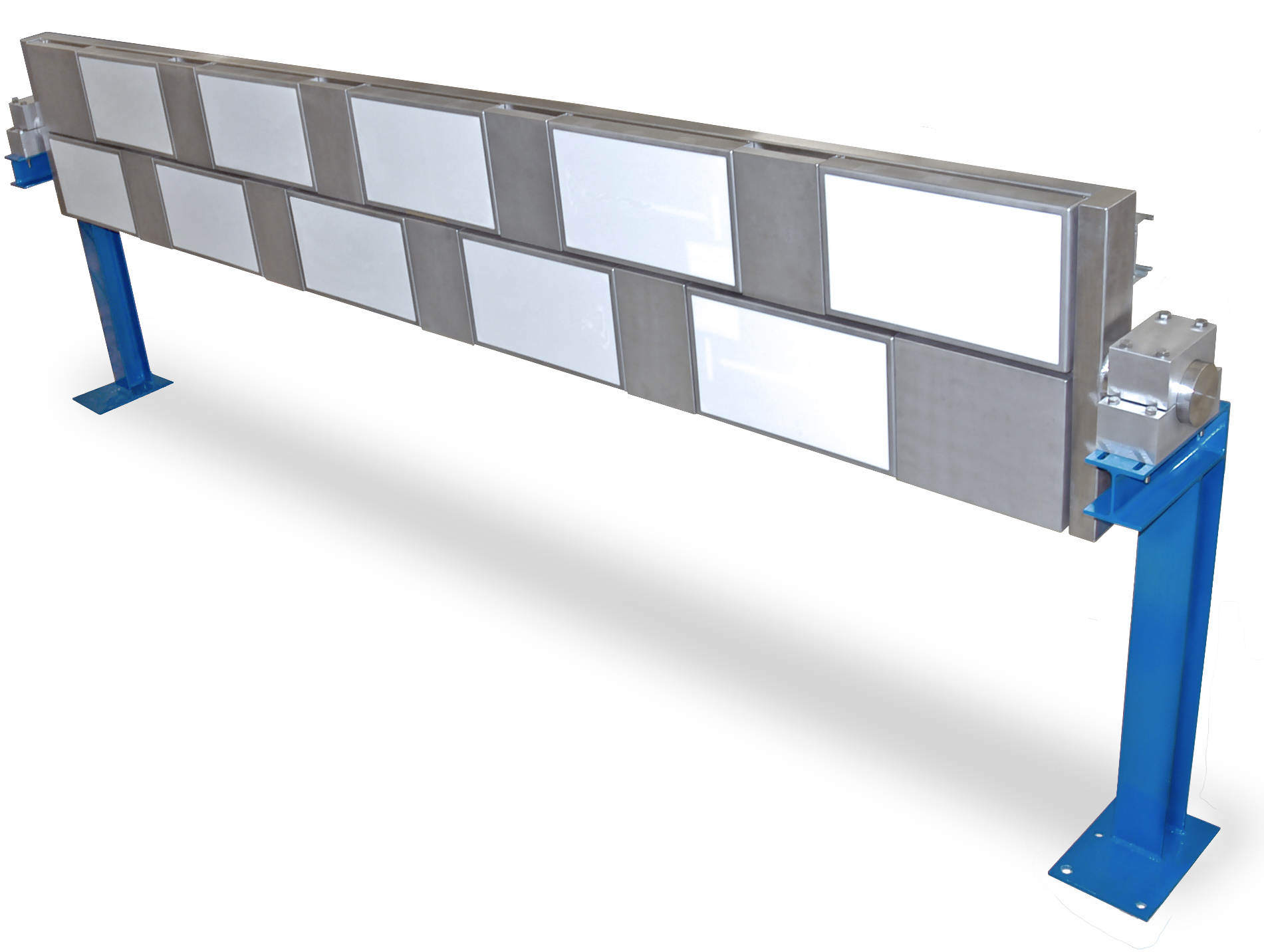

Conveyor-applications, non-divideable, stainless-steel construction.

|

|

The high quality HQ conveyors for METAL SHARK® Metal Detectors are available in standard as well as custom-made versions. They are suitable for permanent and reliable application even in harshest environments with highest quality standards (like in the food industry).

|

|

Flat-sensor for mounting above and below the product.

|

|

Ultra-high sensitivities for products being extra wide and flat. The product is positioned close to the sensor-surface.

|

In the textile production process, it may always happens that some staple and broken needle can be found in the final product. In order to protect both the end user and one's own brand from harm, different potential metal hazards must be identified rapidly.

In the textile production process, it may always happens that some staple and broken needle can be found in the final product. In order to protect both the end user and one's own brand from harm, different potential metal hazards must be identified rapidly.