| PIP |

| Metal Detector | |||

The METAL SHARK® Metal Detectors operate on the principle of inductance measurement. All types of metal are detected. However, magnetic metals are detected more reliably than non-magnetic ones. The method of measurement also makes it possible to detect metal particles inside the product or in non-metal packaging.

|

|||

|

Improved performance results from Cassel′s exclusive Four-Quadrant technology, which allows for a 360 degree freestyle teach area around the product effect, significantly increasing sensitivity. Cassel equipment readily adjusts settings to detect metals even in such products as cheese and high-salt content foods, where detection can be a challenge. Setting standards for testing is simple. Users are guided through a series of easy-to-understand, high-color screens. An on-board “teaching assistant” offers help, if needed. Password protection ensures that only authorized users can operate the equipment. Documentation of data required by HACCP, IFS, BRC and GMP is automatically recorded by METAL SHARK 2A. Metal contaminant detections, changes in parameter settings or other data is logged, along with the time and date. Reports can be downloaded to a Windows-based PC for permanent storage and record-keeping. Cassel Metal Detectors can also be programmed to automatically remind the operator to test equipment performance at pre-set intervals. Features & Benefits of SHARK® 2A Controller:

|

|||

Metal Detectors |

|||

| Digital Metal Detection System | |

| Cassel Official website |

|

The METAL SHARK® 2A controller sets a new industry benchmark for performance, user-friendliness and ease of data storage.

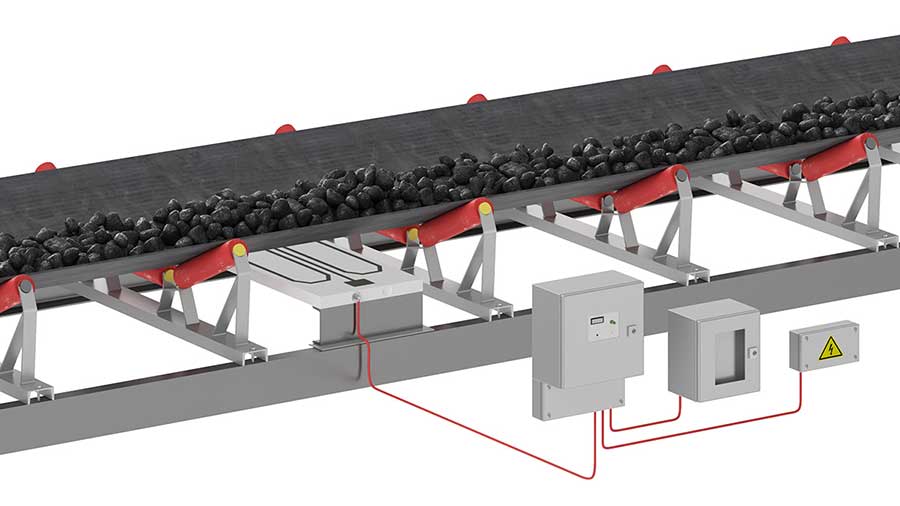

The METAL SHARK® 2A controller sets a new industry benchmark for performance, user-friendliness and ease of data storage. Metal Detector BD (Conveyor)

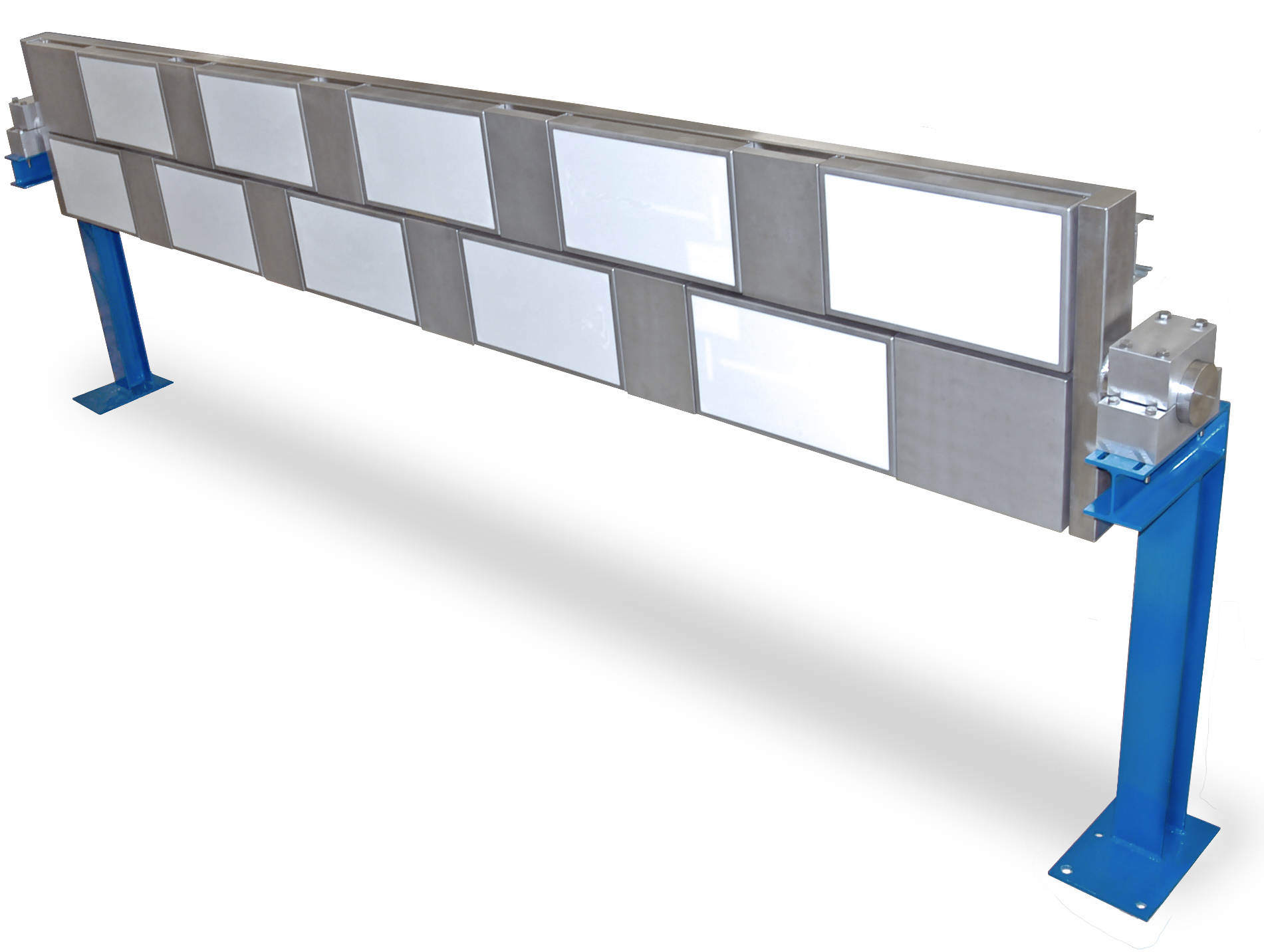

Metal Detector BD (Conveyor) Metal Detector Conveyor HW

Metal Detector Conveyor HW Metal Detector Conveyor HQ SSE

Metal Detector Conveyor HQ SSE Metal Detector GF (downpipe)

Metal Detector GF (downpipe) Metal Detector PH (Pharma)

Metal Detector PH (Pharma) Metal Detector IN LIQUID (pipeline

Metal Detector IN LIQUID (pipeline Metal Detector IN MEAT

Metal Detector IN MEAT Metal Detector FL (Flat Plate)

Metal Detector FL (Flat Plate) Metal Detector R (Ring Sensor)

Metal Detector R (Ring Sensor) Metal Detector BIG

Metal Detector BIG Metal Detector TU (Tunnel)

Metal Detector TU (Tunnel) Metal Detector RECT

Metal Detector RECT Metal Detector OCTA

Metal Detector OCTA Metal Detector RD

Metal Detector RD Metal Detector Combi

Metal Detector Combi Metal Detector Combi-TU

Metal Detector Combi-TU Metal Detector BIGpba

Metal Detector BIGpba Metal Detector QLC

Metal Detector QLC Metal Detector SQ/SQTA

Metal Detector SQ/SQTA SHARK Test Pieces

SHARK Test Pieces SHARKNET

SHARKNET